LLDPE rotationally molded equipment enclosures have impact resistance and pressure resistance. Whether during transportation or during use, the device shell can effectively absorb impact forces and protect the internal device from damage caused by accidental collision or crushing.

Due to the properties of PE and LLDPE materials, the product has good weather resistance and can withstand the effects of UV rays, high temperatures, and harsh weather conditions. This allows the device case to maintain a good appearance and performance even when used outdoors for extended periods of time.

LLDPE Rotomolding Equipment Shell

|

Product material |

PE, LLDPE |

|

Scope of application |

Used to cover and protect internal components of equipment |

LLDPE Rotomolding Equipment Shell is a high-performance shell product designed to provide all-round protection for the core components of industrial equipment. It is made of high-quality polyethylene (PE) and linear low-density polyethylene (LLDPE) materials combined with a rotational molding (Rotomolding) process. This process uses uniform heating and rotating molds to fully extend and integrally mold the material to create a seamless, seamless shell structure with high strength, light weight and wear resistance. The addition of LLDPE material significantly improves the product's flexibility, weather resistance and chemical corrosion resistance, enabling it to operate stably in an extreme temperature range of -40°C to 80°C, and resist the erosion of acids, alkalis, salt spray, oil pollution and most organic solvents. It is suitable for complex and harsh environments such as chemical industry, environmental protection, agricultural machinery, and outdoor power facilities. As an ideal solution in the field of equipment protection, this product is designed to cover and protect internal precision components such as mechanical equipment, electronic instruments, and power systems. It effectively blocks dust, moisture, vibration and external physical shocks through a sealed structure to extend the service life of the equipment. Its lightweight characteristics (low density and light weight) greatly reduce installation and maintenance costs. At the same time, the modular design supports flexible customization of sizes, openings and accessories to meet the needs of diverse equipment forms. The product's surface anti-UV treatment and anti-aging formula can cope with long-term outdoor exposure, avoid deformation or embrittlement caused by light and temperature differences, and ensure long-term protection effectiveness. With the unique advantages of rotational molding technology, there are no welding seams or weak points inside the shell, completely eliminating the risk of leakage. The protection level is significantly higher than that of traditional assembled shells, and is especially suitable for scenarios with strict sealing requirements, such as food processing equipment, medical equipment or marine engineering facilities.

Who are we?

Cixi Junyi Plastic Co., Ltd., since its establishment in 2007, has been located in Cixi, Zhejiang, known as the hometown of rotational molding. The company is strategically located, only 2 kilometers away from Yuyao North High-speed Railway Station, and about 15 kilometers away from the Hangzhou Bay Cross-Sea Bridge. It has convenient transportation and significant geographical advantages.

As China LLDPE Rotomolding Equipment Shell Suppliers and LLDPE Rotomolding Equipment Shell Factory, we have won the trust and support of our customers with our stable product quality, R&D strength and after-sales service. The company's main business covers the design and research and development of floating body products. It specializes in the production of marine floats, warning floats, buoys, navigation marks, pipeline dredging floats and other types of marine equipment floating bodies. It also provides OEM and ODM services to meet the individual needs of customers.

The company has advanced production equipment, including dozens of rotating tower rotational molding machines, shuttle rotational molding machines, swing open flame rotational molding machines, and thousands of product molds to ensure the diversification of foaming types and products inside the floating body. of high quality.

Junyi Plastic's service commitment is that our professional team will provide customers with a full range of pre-sales, sales, and after-sales services to ensure that customers can receive high-quality technical support. We value the trust of our customers and always adhere to the service concept of "customer-centric, creating value for customers". In the service process, we continue to accumulate experience, improve service quality, and strengthen service intensity. Through unremitting exploration and continuous improvement, we have established a high-quality and complete after-sales service system. We always start from the actual needs of customers, not only solving customers' worries, but also committed to improving the added value of products.

-

Founded In

0+ -

Production Lines

0+ -

Employee

0+ -

Plant Area

0㎡+

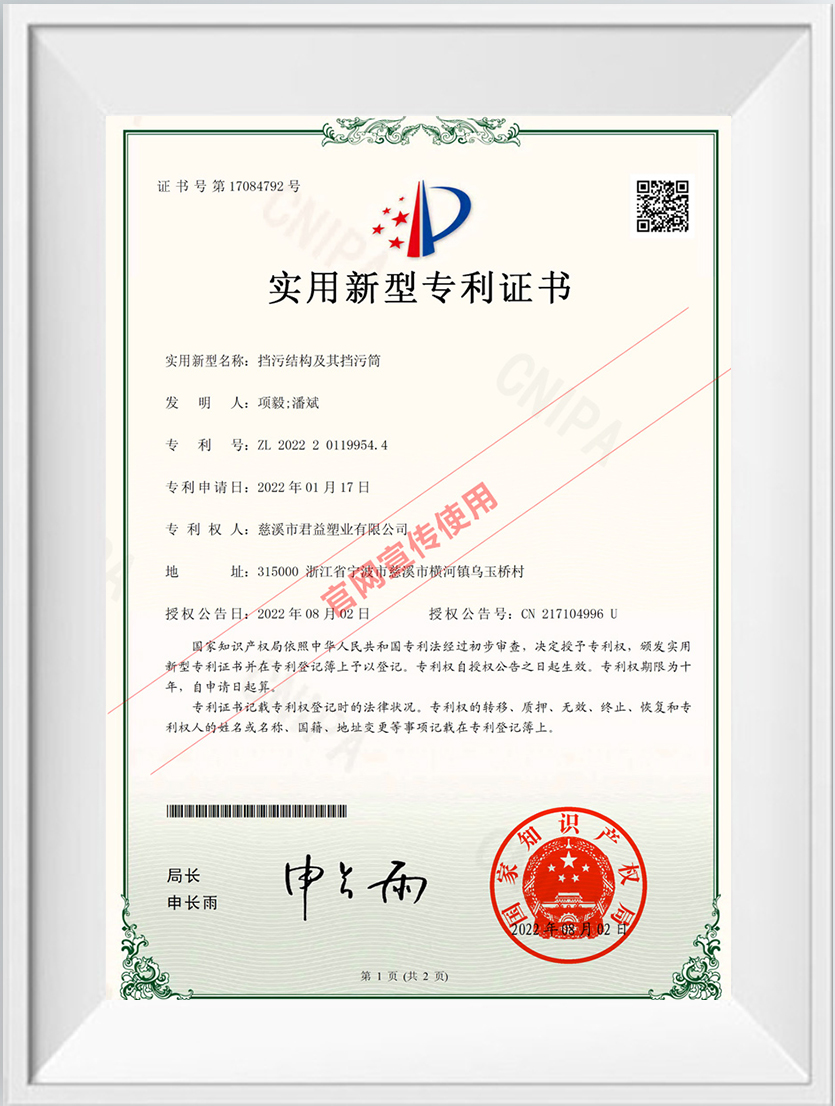

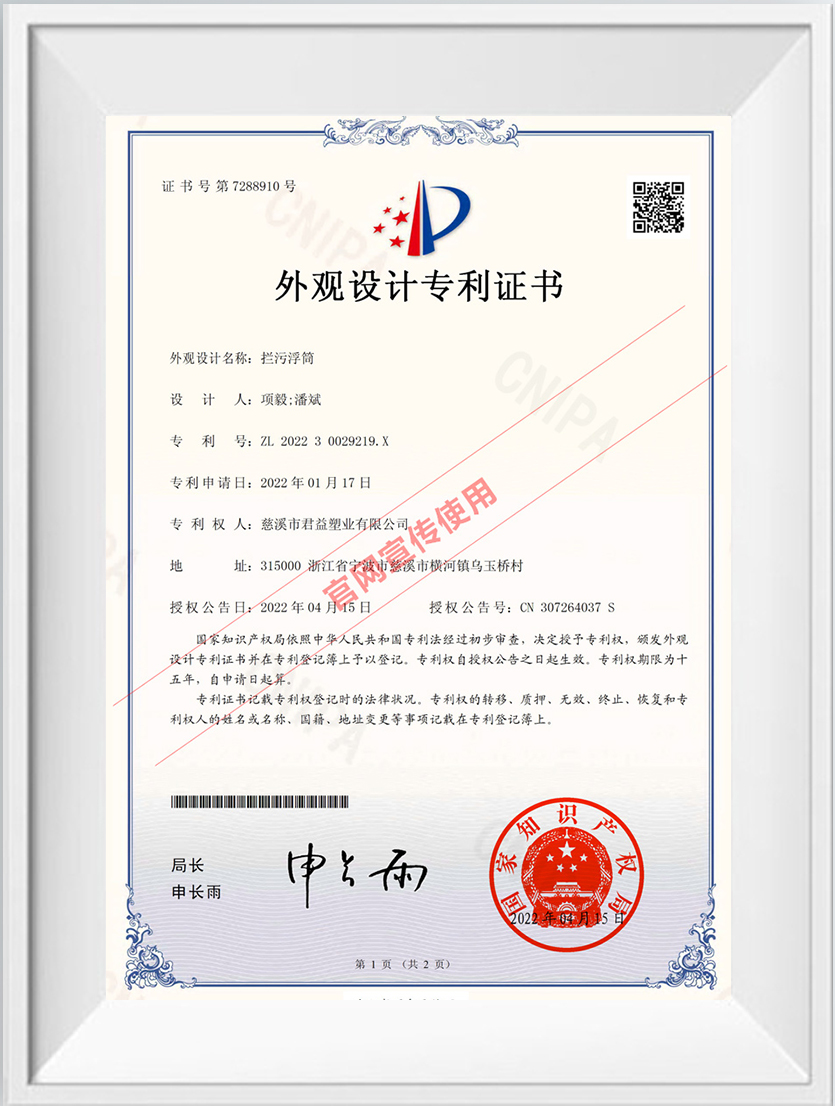

Qualifications we have obtained

Authentic reliable quality naturally stands out and fears no comparison. Professional LLDPE Rotomolding Equipment Shell Suppliers.

English

English عربى

عربى